Addressing the growing need for sustainable practices, BikeKit offers LLDPE boxes – a recyclable alternative to harmful and toxic FRP boxes that enable Last Mile delivery firms to minimize their environmental impact. Below is a compelling narrative and content showcasing why LLDPE is the future, and FRP (Fiber Reinforced Plastic) is a liability, particularly for large fleets like those with 10,000+ bikes.

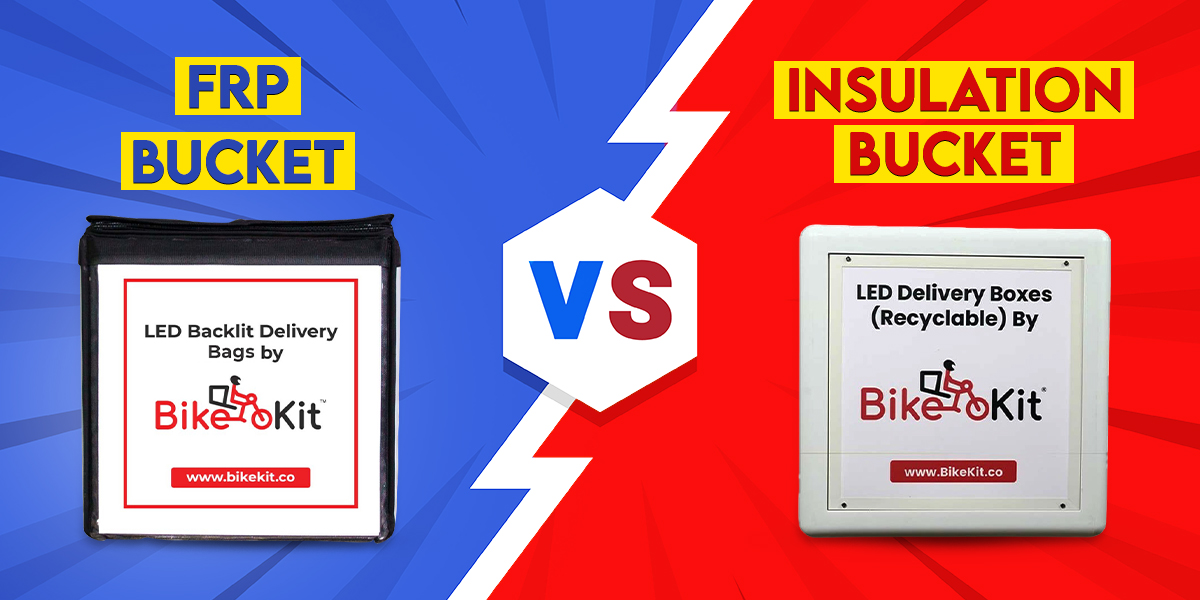

FRP V/s LLDPE: The Sustainability Perspective

The Challenges with FRP

1. Non-recyclable and Environmentally Harmful:

- FRP is non-recyclable due to its composite structure of glass fiber and resin, making it impossible to reprocess or reuse.

- Once discarded, FRP contributes to landfills and environmental pollution, taking hundreds of years to degrade.

2. High Carbon Footprint:

- Manufacturing FRP involves energy-intensive processes and the use of toxic resins, resulting in a high carbon footprint.

- For a fleet of 10,000 bikes, using FRP boxes contributes to tens of thousands of tons of CO₂ emissions annually.

3. Short Lifespan:

- FRP boxes are prone to cracks, brittleness, and fiber breakage, leading to frequent replacements.

- This creates additional waste and increases operational costs.

4. Toxic Waste:

- Disposal of FRP often leads to the release of toxic chemicals that contaminate both soil and water.

- Delivery companies using FRP contribute to ecological harm and a negative environmental impact.

Toxic Waste Calculation: FRP V/s LLDPE for a Fleet of 10,000 Bikes

Assumptions:

Fleet size: 10,000 bikes.

Box weight: 10 kg per box.

Replacement cycle: Every 2 years.

Impact of Using FRP Boxes:

1. Non-recyclable Waste Generated:

- Replacement every two years means: 10,000 bikes x 10 kg/box is 100,000 kg (100 metric tons) of waste every two years.

- Over 10 years, this results in 500 metric tons of waste.

Waste Impact: 500 metric tons of non-recyclable waste that will sit in landfills for hundreds of years.

2. Carbon Footprint:

- FRP production and disposal have a high carbon footprint due to energy-intensive processes and the use of toxic materials.

- Estimated emissions per box production is 10 kg of CO₂ per box.

- For 10,000 bikes it will be 100,000 kg of CO₂ every replacement cycle.

- Over 10 years (5 cycles), it’ll result in 500 metric tons of CO₂.

Toxic Waste: FRP disposal releases harmful chemicals into soil and water, contributing to pollution and environmental degradation.

LLDPe:

Recyclable and Sustainable:

- LLDPE boxes are 100% recyclable. At the end of their lifecycle, they can be reprocessed into new materials.

- Since the material is recycled, waste generated per cycle is 0 metric tons.

Marketing Message for Sustainability:

FRP boxes are not only harmful to the environment but also costly in the long run. Over 10 years, a fleet of 10,000 bikes using FRP generates 500 metric tons of non-recyclable waste and significant carbon emissions. LLDPE is the sustainable solution with zero waste, lower carbon footprint, and enhanced durability. Choose LLDPE for a greener future and a smarter investment.

.jpg)